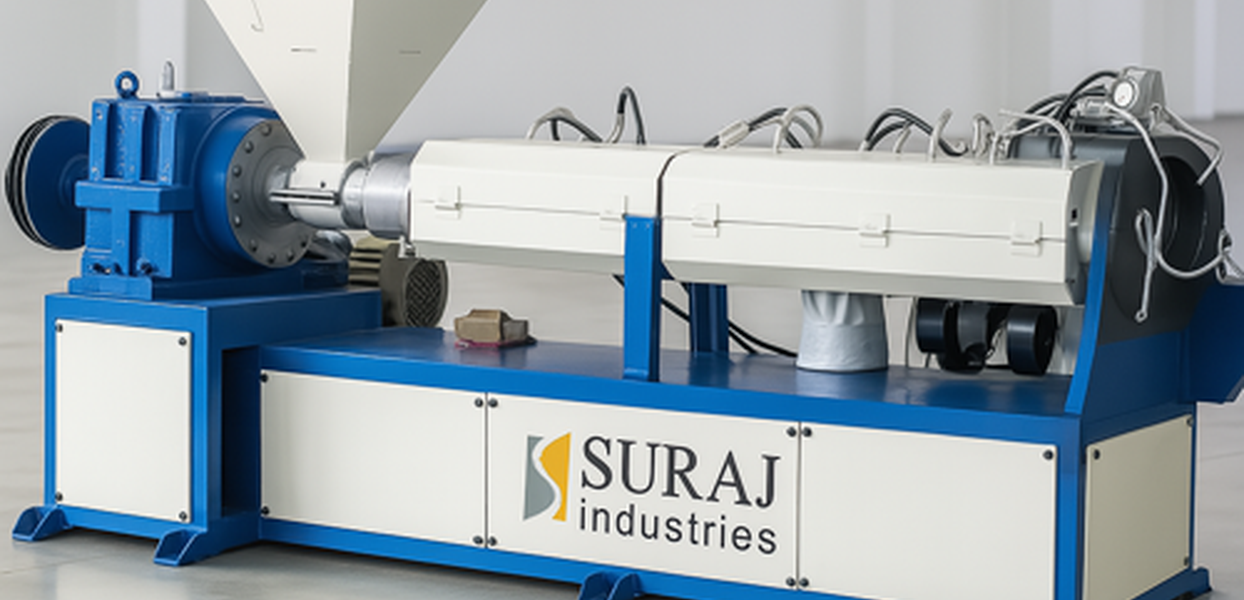

Plastic Pelletizer Machine for HDPE and LDPE

Plastic pelletizer machine for HDPE and LDPE converts washed films, bags, liners, and raffia into uniform, high-strength pellets. Suraj Industry builds robust, energy-efficient lines that deliver stable melt, consistent pellet geometry, and dependable 24×7 recycling performance across India.

Working Principle and Process Flow of Plastic Pelletizer Machine for HDPE and LDPE

Clean, dried HDPE/LDPE flakes or film are metered into the hopper, plasticized in multi-zone heated barrels, filtered through an automatic screen changer/gear-pump, and extruded via die. Strands are water-cooled or hot-cut, then pelletized and dried for reuse.

Types of Plastic Pelletizer Machines for HDPE and LDPE

- Single-screw pelletizing line for films, bags, and regrind

- Twin-screw compounding pelletizer for blends, fillers, and additives

- Vented extruder for moisture/volatiles control in washed film

- Water-ring die-face cutting system for consistent round pellets

- Strand pelletizing system with adjustable cut length and easy inspection

Key Features and Specifications of Plastic Pelletizer Machine for HDPE and LDPE

- Corrosion-resistant stainless contact parts and heavy-duty frames

- Optimized L/D screw design for LDPE melt flow and HDPE viscosity

- Multi-zone PID heaters with automatic temperature control and insulation

- Automatic screen changer and optional gear-pump for stable pressure

- Die-face hot-cut / water-ring / strand pelletizer options with PLC–HMI

Applications of Plastic Pelletizer Machine for HDPE and LDPE

- Converts HDPE and LDPE scrap into uniform pellets for film blowing, pipe extrusion, blow molding, and injection parts, reducing virgin resin usage and improving sustainability across packaging, construction, and consumer goods manufacturing.

- Supports post-consumer and post-industrial recycling by transforming printed films, carry bags, liners, and raffia into reusable granules that lower production costs and stabilize supply chains for domestic and export markets.

- Generates recycled pellets with controlled MFI and low gel count for smooth downstream processing, improving product consistency, machine uptime, and yields in film, sheet, profile, and molded product lines.

- Integrates with washing, drying, and densifying modules, enabling flexible throughput, automatic filtration, and pelletizing choices to match varying feedstock quality and customer specifications.

Benefits of Plastic Pelletizer Machine for HDPE and LDPE

- Automates feeding, plasticizing, filtration, and cutting for higher throughput and uniform pellets that boost film, pipe, and molding efficiency.

- Reduces energy per kg via optimized screw profile, insulated zones, inverter drives, and stable melt pressure—lowering operating costs and carbon footprint.

- Delivers durable performance with wear-resistant parts, easy-access maintenance, and rugged gearboxes that extend service life and minimize downtime.

- Improves pellet quality—tight size distribution, controlled MFI, and minimal moisture—ensuring smooth extrusion, fewer defects, and less rework.

- Built-in safety guards, emergency stops, and temperature/pressure interlocks enhance operator safety and regulatory compliance.

Leading Plastic Pelletizer Machine Manufacturers in India

Suraj Industry engineers HDPE/LDPE pelletizing lines tailored to feedstock and capacity targets. We provide end-to-end support—design, installation, training, and responsive service—to achieve consistent quality and reliable, continuous production.

Maintenance and Safety Tips for Plastic Pelletizer Machine for HDPE and LDPE

- Lubricate bearings, gearbox, and drive components as per schedule

- Inspect heaters, thermocouples, pressure sensors, and cables routinely

- Clean hopper, screen changer, gear-pump filters, and die head regularly

- Maintain stable water-ring/strand cooling and dry feed to prevent gels

- Use PPE; follow lockout–tagout, hot-surface, and rotating-parts precautions

Plastic Pelletizer Machine for HDPE and LDPE — FAQs

Contact Details

Talk to our specialists today for tailored solutions and fast assistance.