Introduction to Plastic Granules Making Machine

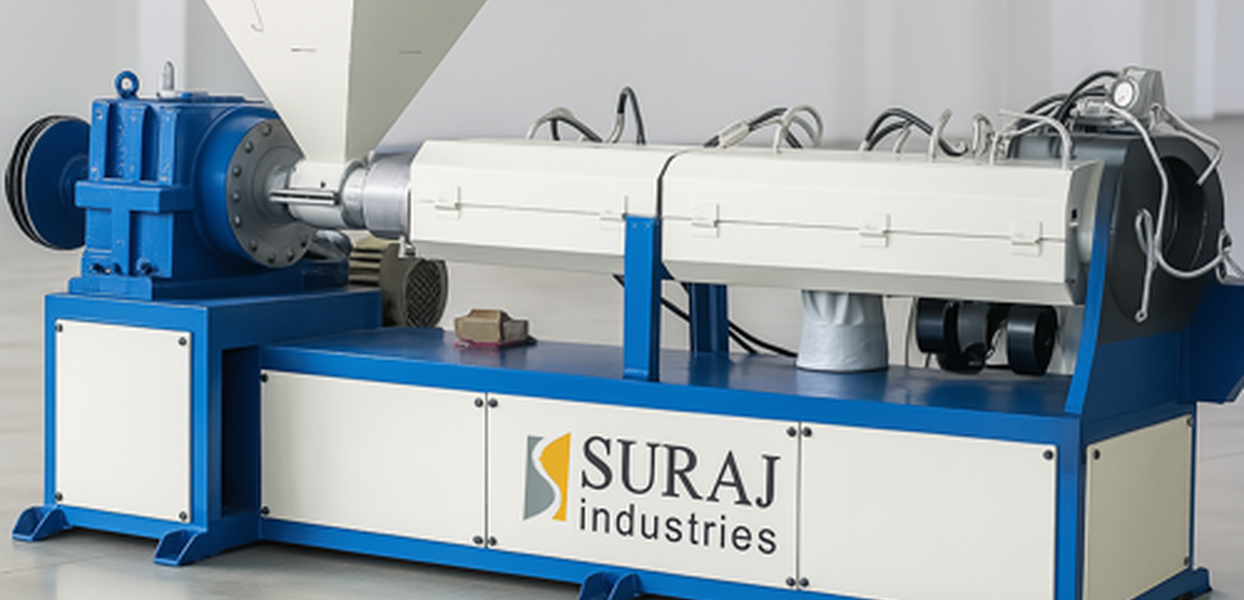

Suraj Industry is a trusted name in the manufacturing of plastic granules machines in India. These machines are designed to transform raw or waste plastic into high-quality granules, which can be reused in various plastic production processes. Known for durability, efficiency, and low maintenance, our machines are widely used in the recycling industry.

Working Principle and Process Flow

A plastic granules machine works by feeding raw or waste plastic material into a hopper, where it is melted using controlled heating. The molten plastic passes through a screw extruder and is shaped into strands, which are then cooled and cut into uniform granules. Suraj Industry ensures each step is optimized for maximum efficiency and output.

Types of Plastic Granules Machines

- Single-screw granules machine

- Twin-screw granules machine

- High-speed granules making machine

- Water-ring cutting granules machine

- Strand pelletizing granules machine

Key Features and Specifications

- Robust stainless steel construction

- High-output screw and barrel design

- Energy-efficient heating system

- Automatic temperature control

- Low maintenance requirements

Applications in Recycling Industry

- Efficient recycling of HDPE, LDPE, PP, PET, and PVC materials for re-use in industrial and commercial manufacturing processes.

- Reprocessing of post-consumer and post-industrial plastic film waste into high-quality granules suitable for multiple applications.

- Production of durable plastic granules used in the manufacturing of pipes, sheets, packaging materials, and other industrial products.

- Manufacturing of high-grade injection moulding raw material to create precision-engineered plastic components for various industries.

Benefits of Using Plastic Granule Machines

- Significantly reduces plastic waste by transforming discarded plastic into reusable granules, thereby promoting sustainable recycling practices and reducing environmental pollution.

- Produces granules with consistent size and high quality, ensuring better compatibility with extrusion, moulding, and other manufacturing processes without causing production defects.

- Offers low operational costs and minimal energy consumption, making it an economical investment for both small-scale workshops and large industrial production units.

- Ensures long-lasting performance due to its robust stainless steel construction, corrosion resistance, and low-maintenance design, reducing downtime and repair expenses.

- Boosts production efficiency by streamlining the granulation process, allowing faster material turnaround and enabling industries to meet higher market demands with ease.

Top Manufacturers and Suppliers in India

Suraj Industry is recognized among the best plastic granules machine manufacturers in India for delivering advanced, durable, and efficient machines that meet industry standards and client expectations.

Maintenance and Safety Tips

- Regular lubrication of moving parts

- Inspection of heating elements and electrical systems

- Cleaning the hopper and extruder after production

- Wearing safety gear during operation

- Following the manufacturer’s service schedule

Plastic Granules Machine FAQs – Everything You Need to Know

Contact Details

Talk to our specialists today for tailored solutions and fast assistance.