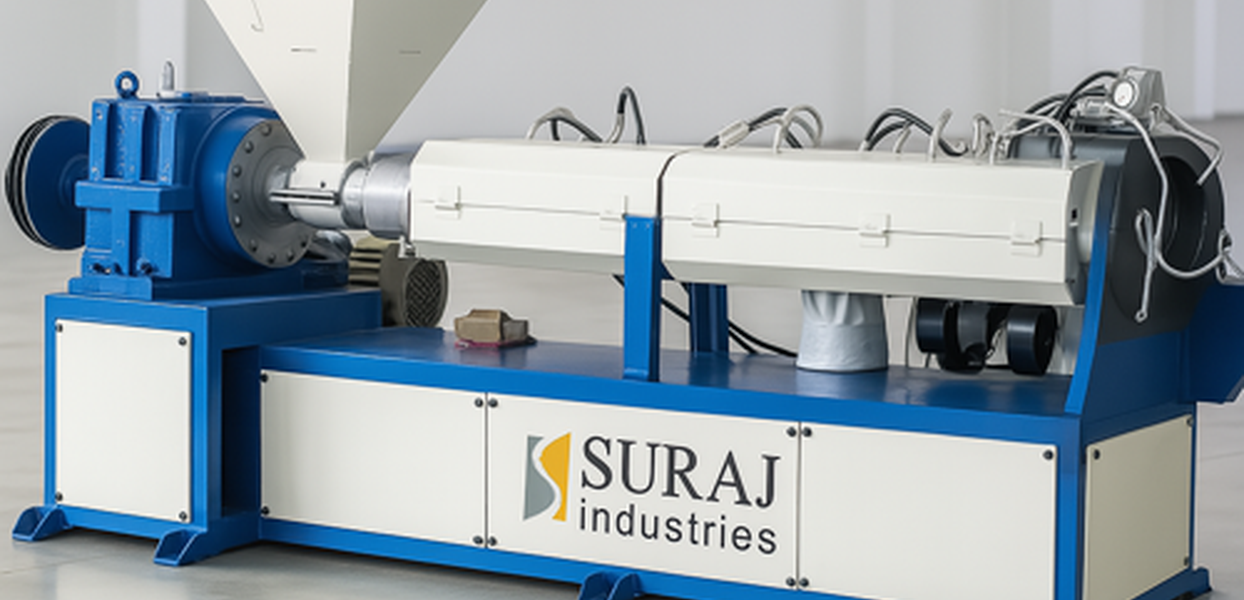

Automatic Plastic Granules Machine for Recycling

Suraj Industry offers an automatic plastic granules machine for recycling that converts sorted polymer waste into high-quality pellets. Our robust, energy-efficient systems ensure consistent output, simplified operation, and reliable performance for continuous industrial recycling lines across India.

Working Principle and Process Flow of Automatic Plastic Granules Machine for Recycling

Cleaned plastic flakes are fed through a hopper, melted in controlled heating zones, and conveyed by a precision screw. The melt is filtered, extruded into strands, water-cooled, and pelletized into uniform granules ready for downstream manufacturing.

Types of Automatic Plastic Granules Machines for Recycling

- Single-screw granulation line for general-purpose polymers

- Twin-screw compounding granulator for filled or blended materials

- High-speed granules line for elevated throughput targets

- Water-ring cutting system for consistent pellet geometry

- Strand pelletizing system with adjustable cutting length

Key Features and Specifications of Automatic Plastic Granules Machine for Recycling

- Heavy-duty stainless steel construction with corrosion resistance

- Optimized screw–barrel design for stable melt and output

- Energy-efficient multi-zone heaters with auto temperature control

- Melt filtration, water-cooling trough, and precision pelletizer

- Low maintenance, safety interlocks, and user-friendly controls

Applications of Automatic Plastic Granules Machine for Recycling

- Converts HDPE, LDPE, PP, PET, and PVC waste into uniform pellets for use in packaging, automotive, construction, textiles, and electrical industries, reducing virgin material demand and promoting sustainable manufacturing practices globally.

- Supports post-consumer and post-industrial recycling by transforming discarded plastic into reusable granules, lowering production costs, promoting circular economy principles, and ensuring compliance with stringent environmental regulations across diverse industrial sectors.

- Produces recycled pellets suitable for film, sheet, pipe, and molded parts manufacturing, meeting quality standards for domestic and export markets while supporting cost efficiency and sustainable supply chain operations.

- Integrates seamlessly into existing recycling lines with customizable throughput, pelletizing options, and automation levels, offering flexibility to meet evolving market demands, customer requirements.

Benefits of Automatic Plastic Granules Machine for Recycling

- Automates feeding, melting, filtration, and pelletizing to increase throughput, reduce manual work, and deliver uniform pellets that enhance extrusion and molding efficiency.

- Lowers energy costs through optimized heating zones, efficient screw design, and precision controls, reducing the carbon footprint, improving profitability, and supporting large-scale plastic recycling with consistent product quality and dependable machine performance.

- Provides durable stainless steel construction, wear-resistant parts, and easy maintenance access, minimizing downtime, extending service life.

- Improves pellet quality by maintaining consistent shape, size, and polymer stability, enabling smooth downstream processing in packaging, construction, automotive, and industrial sectors without costly production interruptions or frequent machine adjustments.

- Enhances safety with integrated guards, automated shutdown systems, temperature monitoring, and ergonomic controls, reducing risks, increasing operator comfort, and aligning with strict safety standards for responsible plastic recycling operations worldwide.

Leading Automatic Plastic Granules Machine Manufacturers in India

Suraj Industry is recognized for advanced, durable, and efficient recycling granulation lines. We build systems tailored to your materials, capacity goals, and product specs—backed by installation, training, and responsive after-sales support.

Maintenance and Safety Tips for Automatic Plastic Granules Machine for Recycling

- Lubricate bearings, gearbox, and drive components as per schedule

- Inspect heaters, thermocouples, and electrical panels routinely

- Clean hopper, screens, and die head to prevent contamination

- Wear PPE; follow lockout–tagout and hot-surface precautions

- Adhere to preventive maintenance for consistent output and safety

Automatic Plastic Granules Machine for Recycling — FAQs

Contact Details

Talk to our specialists today for tailored solutions and fast assistance.